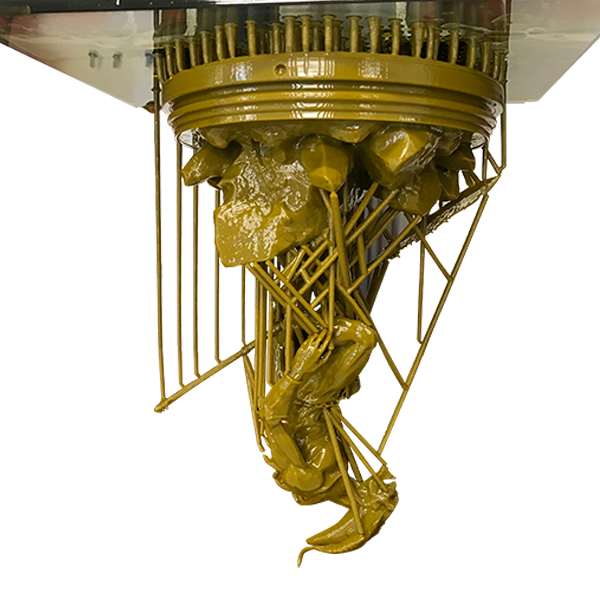

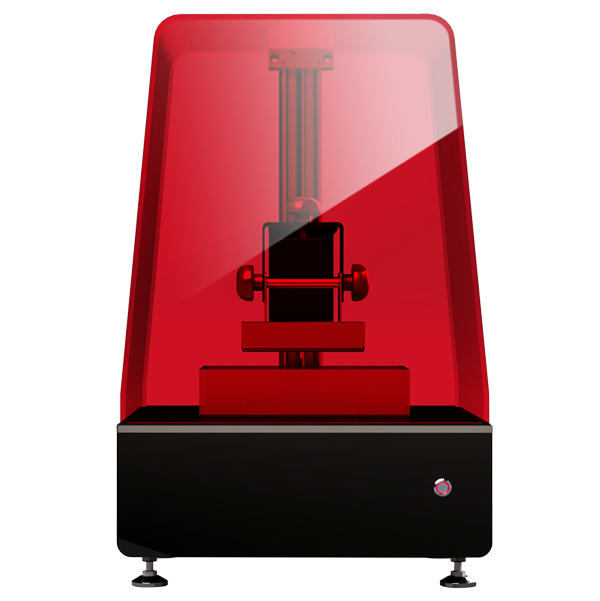

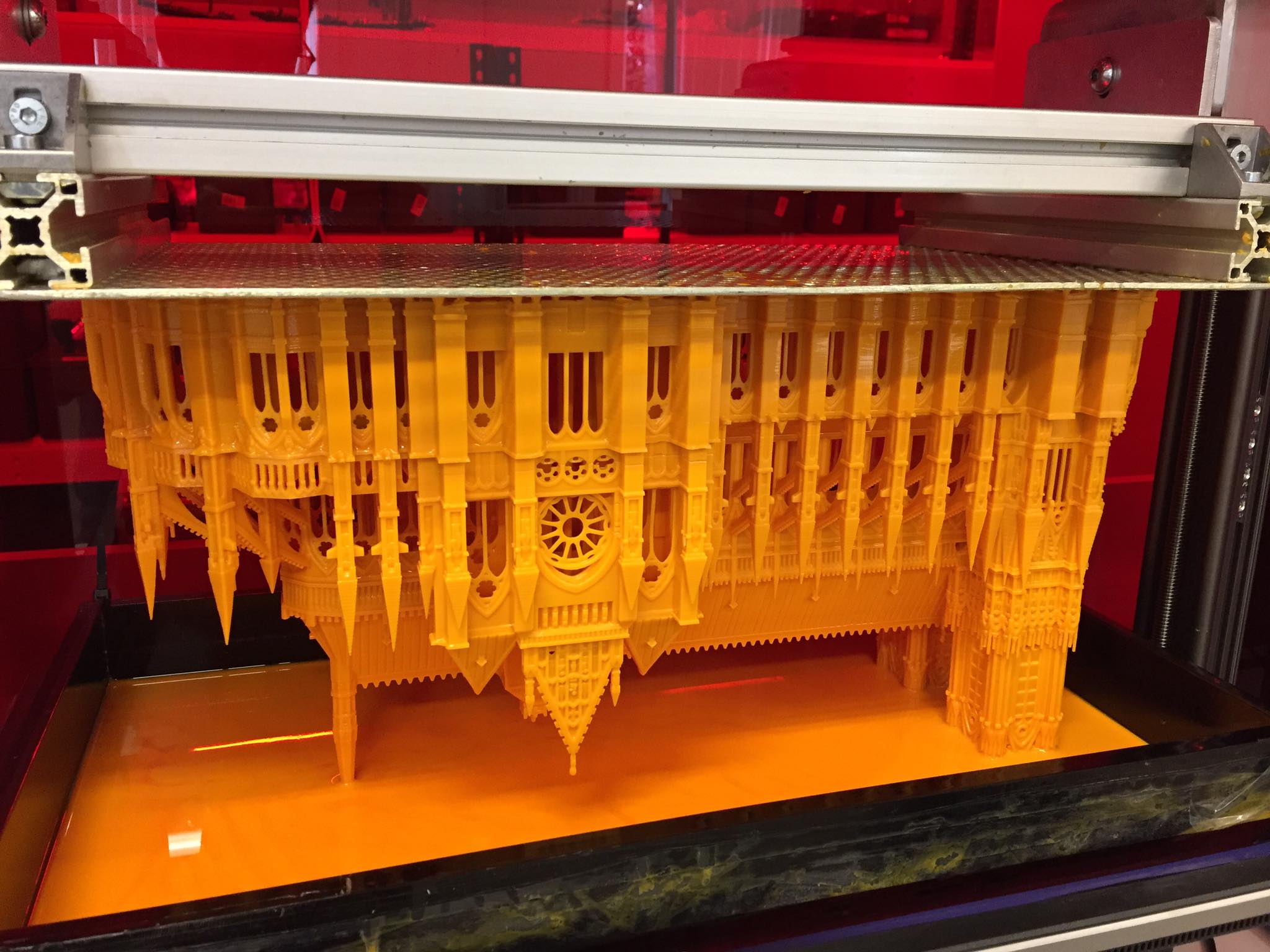

Liquid Crystal is a very simple concept – use the daylight emitted from an LCD screen to polymerise resin that is tailored to that wavelength and intensity. All other 3D printers that polymerise resin use a combination of both daylight and UV light at considerably higher intensities. Photocentric has been able to make this work by developing the world’s most sensitive daylight resins. The power of this idea is profound. What might seem to be disadvantages- that it works solely in daylight and it works with orders of magnitude lower intensities of light are actually its greatest strengths.

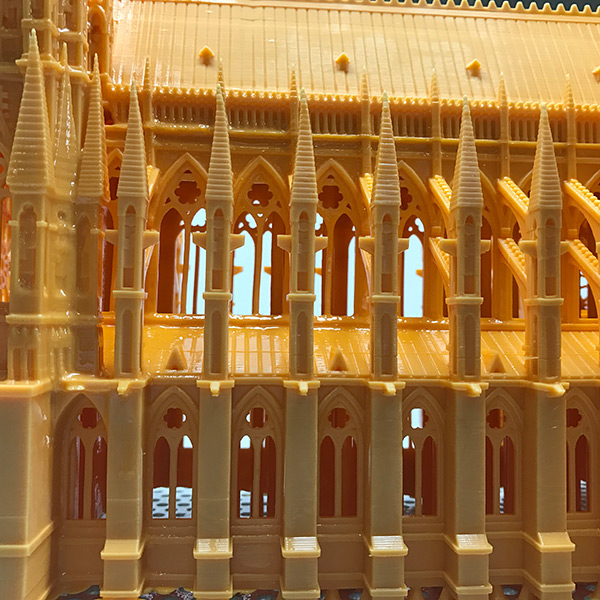

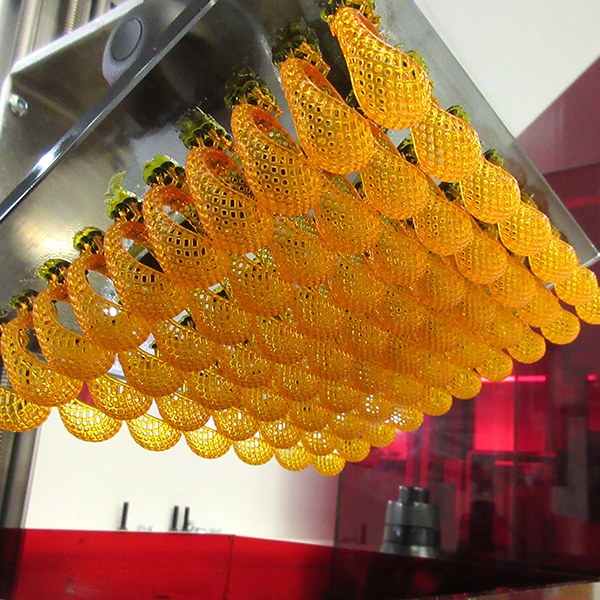

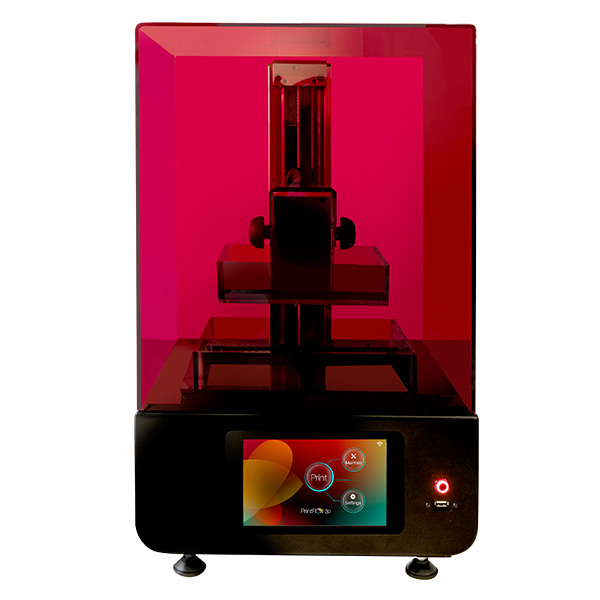

Utilising mass produced screens designed for use in mobiles, handheld devices enable us to use the highest resolution screens, offering phenomenal value for money, which we can then pass onto our customers. The very low intensity luminance from these screens, an order of magnitude lower than produced by digital light projectors and lasers, means there is no scattered light to create unwanted overcure – light used to harden a layer is simply absorbed at that depth and not passed on.

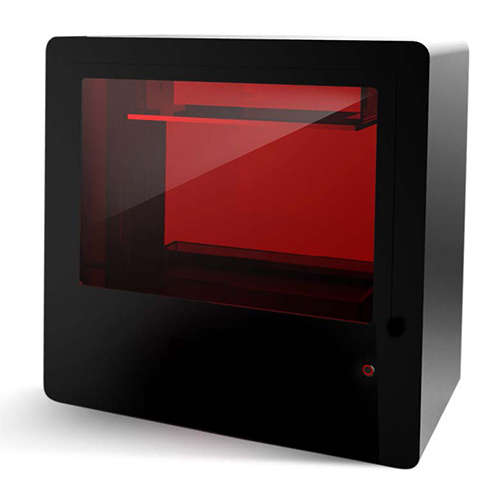

The opportunities are limitless; higher and higher resolution screens becoming available in all formats from mobiles to large format televisions provide the lowest cost imaging systems ever imagined.